Why Choose Meiyahg Mold Release Agent

Leader of Mold Release Agent Manufacturer

20 Years+ Experience

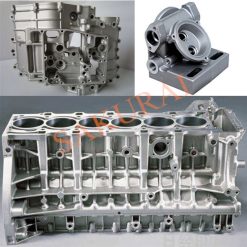

Dongguan Meiya Chemical Co., Ltd has been around for almost 20 years. It specializes in research, development, and production of high-end mold release agent.

Production capacity

Production capacity of chemical release agent is 150 Tons per day, to ensure worldwide supply.

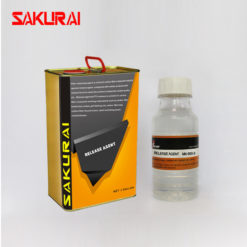

OEM/ODM Service

Our company accepts mold release agent customization service.

High Product Stability

Use a smart vertical R&D system. This system includes unsteam research on raw materials, midstream formulation design and production, and downstream validation that informs midstream manufacturing. This method ensures stable product production.

Fortune 500 Collaboration Experience

Meiyahg collaborates with many Fortune 500 companies, like HUAWEI, Alibaba, and BMW.

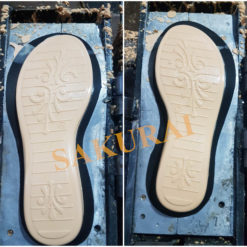

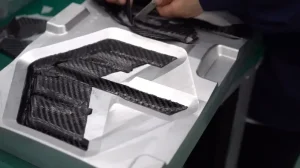

Cost-Effective

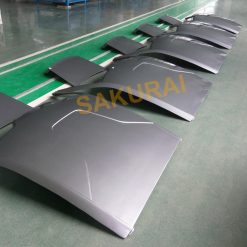

Our release agent provides excellent lubrication and creates an even film. It enhances demolding performance and increases product productivity, saving on labor costs.