FAQ

If you have any questions about the Polythane mold release agent, please feel free to contact- Basic components:

- Paraffin: 5–20 parts

- Stearic acid: 5–8 parts

- Plant oil: 5–10 parts

- Emulsifier: 5–8 parts

- Potassium hydroxide: calculated amount

- Other auxiliary materials: as needed

- Ethyl paraben: as needed

- Deionized water: to 100 parts

- Emulsified wax: 10%–15%

- Methyl silicone emulsion: 15%–20%

- Modified silicone emulsion: 5%–8%

- Deionized water: 50%–55%

- Emulsifier: 4.5%–6%

- Additives: 0.5%–1%

- Preservatives: 0.3%–0.5%

- By Carrier: Water-Based and Solvent-Based

- By Chemistry: Silicone-Based and Non-Silicone-Based

- By Lifespan: regular mold release agent and semi-permanent Polyurethane release agent

- By Usage: Internal release agent and external release agent

- by Active Substances: Silicone Series, Wax Series, Fluorine Series, Surfactant Series, Inorganic Powder Series, Polyether Series

Water-Based vs. Solvent-Based Release Agents

| Feature | Water-Based | Solvent-Based |

| Carrier | Water | Organic Solvents (e.g., naphtha) |

| Environment & Safety | Low VOC, non-flammable, safer | High VOC, flammable, health risks |

| Performance | Thin film, requires mold temp control | Fast evaporation, quick film-forming |

| Applications | Plastics, rubber, silicone; eco-friendly industries | Traditional fields, usage declining |

| Cost | Higher initial cost, lower long-term costs | Lower initial cost, higher hidden costs |

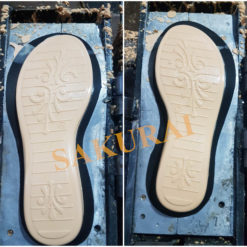

- Durability: Semi-permanent release agent creates a stable film on the mold surface. This allows multiple demolding cycles without frequent reapplication.

- Versatility: It works with various materials like plastics, rubbers, and metals. It's suitable for different manufacturing needs.

- Cost Efficiency: Their long-lasting feature reduces the need for frequent applications. This can lower material and labor costs over time.

- Environmental Friendliness: Many are water-based, or have low VOC content, make them more Eco-friendly

- Spraying: Use an HVLP(high volume, low pressure) spray gun or an aerosol can. It's suitbale for large Polyurethane mold production.

- Brushing: This method is suitable for small molds or detailed areas. It allows for precise application.

- Wiping: Use a clean, lint-free cloth t wipe a thin, uniform layer onto the mold surface.

- Water-based: Usually between 10-50 minutes(depend on the environment temprature and humidity)

- Oil-based: It takes longer to dry, usually several hours or more. the drying time depends on the time of oil and environment.

- Semi-permanent: Just need 15 miniutes for each layer to dry. After the last layer, let it sit at room tempreature for at least 30 miniutes to fully cure.

- Lack of release agent: If not enough release agent is used, it won't form a complete barrier on the mold. It will lead to the sticking of release agent.

- Moisture or Impurities in the mold release agent: If the mold release agent has moisture or impurities, it can affect demolding result, and sticks to the mold.

- Improper types of release agent: Different mold process need specific types of release agent

- Mold surface issue: A rough mold surface, rust, or undercuts can affect how well the release agent adhere and performs.

- Improper molding process parameters: Facts like excessively high pouring tempreture or insufficient curing time will lead to the product sticking to the mold.

- Ensuring the release agent is applied insufficient

- Check the quliaty of mold release agent

- Choose the correct mold release agemt according to the process and material

- Maintain the mold regularly, keeping its surface clean and smooth.

- Optimize the molding process parameters to ensure the product is fully cured before demolding.