The injection molding industry plays a key role in modern manufacturing. It allows for the mass production of high-quality plastic parts quickly. As demand rises in automotive, medical, consumer goods, and aerospace, picking the right mold manufacturer is important. The best U.S. firms shine by using technologies like multi-cavity molds and hot runner systems. They also ensure quality with ISO-certified processes and have strong industry experience. This list ranks the top 10 injection molding manufacturers in the USA.

Top 10 Injection Molding manufacturers in the USA

| Company | Location | Year Founded | Size (Employees) | Main Services/Products | Certifications | Unique Strengths |

|---|---|---|---|---|---|---|

| Upminc | USA | 2002 | 200 | Custom injection molding, prototyping, production | ISO 9001 | Fast lead times, digital twins, automation |

| REX Plastics | Vancouver, WA | 1971 | 50 | Custom injection molding, mold design, assembly | ISO 9001 | Personalized service, complex parts |

| MSI Mold | Shelby Township, MI | 2005 | 40 | Injection molding, mold making, prototyping | ISO 9001 | Fast turnaround, responsive engineering |

| Proto Labs, Inc. | Maple Plain, MN | 1999 | 2,500 | Rapid prototyping, custom injection molding, on-demand | ISO 9001, ISO 13485 | Digital manufacturing, speed, precision |

| GSH Industries, Inc. | Cleveland, OH | 1986 | 100 | Injection molding, extrusion, assembly | ISO 9001 | Small/large runs, new materials, automation |

| Kemal Manufacturing | California, USA | 1995 | 300 | Custom injection molding, mold design, prototyping | ISO 9001, ISO 13485 | Tight tolerances, sustainability, large fleet |

| Britech Industries | Stuart, FL | 1984 | 60 | Injection molding, rubber molding, assembly | ISO 9001 | Flexible schedules, operator training |

| Jones Plastic & Eng. | Louisville, KY | 1961 | 1,000 | Injection molding, assembly, product design | ISO 9001, IATF 16949 | Large-scale, automation, automotive focus |

| The Rodon Group | Hatfield, PA | 1956 | 120 | Injection molding, mold design, assembly | ISO 9001 | Sustainability, robotics, turnkey solutions |

| Ironwood Plastics Inc. | Ironwood, MI | 1979 | 200 | Injection molding, insert molding, overmolding | ISO 9001, ISO 14001 | Advanced materials, fiber-reinforced compounds |

Upminc-Best Injection Molding Manufacturers USA

Upminc is in the middle of the USA. It is a top plastic molding manufacturer. The company started in 2002 and has over 200 workers. Upminc does custom injection molding and rapid prototyping. It also handles big production jobs. Upminc has ISO 9001 certification. This shows it cares about quality. The company uses automation and digital twins to control its process. Upminc is known for making good products fast. Customers like Upminc for its strong engineering help and flexible tooling.

REX Plastics

REX Plastics is in Vancouver, Washington. It started in 1971 and is family-owned. The company has about 50 workers. As one of the leading USA injection molding companies, REX Plastics mainly focuses on custom injection molding and mold design. It also offers assembly services. The company makes high-quality products for electronics and cars. It also serves consumer goods. REX Plastics has ISO 9001 certification. It trains its workers often. The company is known for great customer service. It can make complex injection molded parts. REX Plastics works with material suppliers to make special resin formulas.

MSI Mold

MSI Mold is a professional plastic injection mold manufacturer with over 20 years of experience in Shelby Township, Michigan. It started in 2005 and has 40 workers. The company does plastic injection molding and mold making. It also offers prototyping. MSI Mold is known for quality and quick work. It uses advanced process monitoring. The company has ISO 9001 certification. MSI Mold can make custom injection molded parts. It serves medical, car, and industrial markets. Customers like MSI Mold for its helpful engineering team and on-time delivery.

Proto Labs, Inc.

Proto Labs, Inc. is in Maple Plain, Minnesota. It started in 1999 and has over 2,500 workers. Proto Labs is one of the biggest plastic mold makers in the USA. The company does rapid prototyping and custom injection molding. It also offers on-demand manufacturing. Proto Labs has ISO 9001 and ISO 13485 certifications. This means it follows strict quality rules. The company uses digital manufacturing and cloud tools. Proto Labs makes high-quality products very fast and with great accuracy.

GSH Industries, Inc.

GSH Industries, Inc. is a professional plastic injection molding company in Cleveland, Ohio. It has helped customers since 1986. The company has 100 workers. GSH Industries does custom injection molding and extrusion. It also offers assembly services. The company makes high-quality products for cars and construction. It also serves consumer markets. GSH Industries has ISO 9001 certification. It can handle small and big production jobs. The company uses new materials and automation to work better.

Kemal Manufacturing

Kemal Manufacturing is one of the leading plastic injection molding manufacturers in California. It started in 1995 and has over 300 workers. The company does custom injection molding and mold design. It also offers rapid prototyping. Kemal Manufacturing has many machines and uses automation. The company has ISO 9001 and ISO 13485 certifications. This shows it cares about quality. Kemal Manufacturing is known for tight tolerances and fast work. The company uses circular economy ideas and cares about the environment.

Kemal Manufacturing uses 75 machines from 30 to 2800 tons. It manages over 80 mold units. The company can make parts with ±0.01 mm tolerances. It delivers on time 98.5% of the time.

Britech Industries

Britech Industries is a professional injection molding company in Stuart, Florida. It has done custom injection molding since 1984. The company has 60 workers. Britech Industries does injection molded plastics and rubber molding. It also offers assembly. The company makes high-quality products for industry and business. Britech Industries has ISO 9001 certification. It is known for custom solutions and flexible schedules. The company trains its workers and uses process certification.

Jones Plastic & Engineering

Jones Plastic & Engineering is in Louisville, Kentucky. It started in 1961 and has over 1,000 workers. The company is a top plastic molding manufacturer in the USA. Jones Plastic & Engineering does custom injection molding and assembly. It also offers product design. The company serves car, appliance, and consumer markets. Jones Plastic & Engineering has ISO 9001 and IATF 16949 certifications. It is known for big production jobs and using automation.

The Rodon Group

The Rodon Group is in Hatfield, Pennsylvania. It started in 1956 and has 120 workers. The company does custom injection molding and mold design. It also offers assembly. The Rodon Group is known for high-quality products and caring for the planet. The company has ISO 9001 certification. It uses advanced robots for production. The Rodon Group focuses on making products easy to recycle and saving energy. It also gives turnkey solutions to clients.

Ironwood Plastics Inc.

Ironwood Plastics Inc. is in Ironwood, Michigan. It has worked since 1979 and has 200 workers. The company does custom injection molding and insert molding. It also offers overmolding. Ironwood Plastics Inc. serves car, industrial, and electronics markets. The company has ISO 9001 and ISO 14001 certifications. It cares about quality and the environment. Ironwood Plastics Inc. is known for handling advanced materials and fiber-reinforced compounds.

How We Ranked Manufacturers

To pick the best injection molding manufacturers, we looked at many things. We checked certifications, experience, technology, customer reviews, and services. These points help us find companies that make good products and give great service.

- There are 555 plastic injection molding companies in the U.S. Most are in the Midwest. This shows that location and skilled workers are important.

- Most companies sell mainly in the U.S. About 76% of mold makers focus on local sales. This helps them deliver on time and keep supply chains strong.

- Company size is important too. The top 10 companies have 150 to 850 workers. This means they can handle big orders and tough jobs.

- More people want injection molding now. IndustryNet says searches went up by 27%. Requests for quotes jumped by 102.1% in 2020.

- Companies also stand out by what they do best. Each one has special skills and areas they focus on.

Conclusion

Picking the right injection molding partner helps your project do better. The best companies in the USA give strong engineering help and use DfM analysis. They find problems early, suggest design fixes, and help pick good materials to save money. Companies get these benefits:

- They spot injection molding problems before they start.

- Part quality gets better and production runs smoother.

- Experts help you finish projects faster.

The table and company profiles make it easy to find top partners. Asking for quotes or advice helps match your project with the right company. Good injection molding projects happen when company skills fit what you need.

FAQ

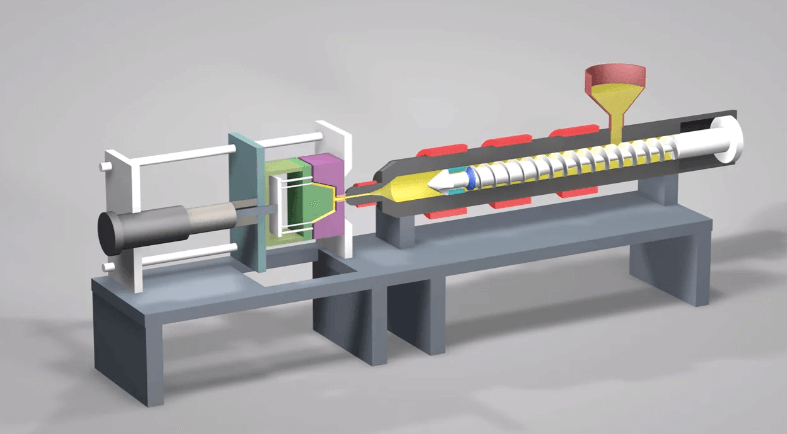

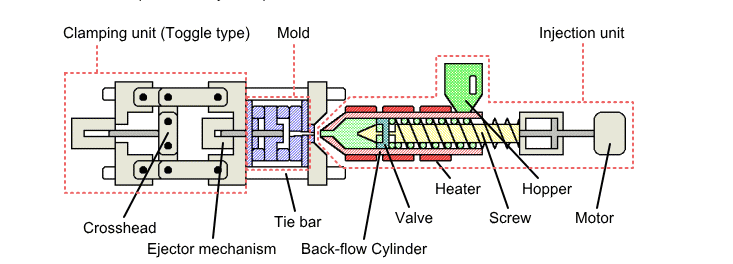

What is plastic injection molding?

Plastic injection molding uses machines to make plastic parts. The machines melt plastic and shape it into items. This process is good for making many of the same thing. Companies use it for car parts, medical tools, and toys.

How do certifications like ISO 9001 help customers?

Certifications like ISO 9001 mean a company follows strict rules. Customers know the company checks its products very well. This helps make sure the products meet important standards.

Why do companies choose U.S. injection molding manufacturers?

Many companies pick U.S. manufacturers for quick delivery and good quality. It is easier to talk with local suppliers. Using U.S. companies also lowers shipping costs and helps the U.S. economy.

What should buyers ask before choosing a manufacturer?

Buyers should ask about certifications and how much the company can make. They should ask how long orders take and about sample rules. It is smart to ask for references and look at past work.