You use mould release oil to help finished products come out of a mould. This oil keeps the mould safe and makes the products better. It also makes the work easier. The worldwide market for mould release oil will be $1,014.4 million in 2024. Experts think it will keep growing. Studies show that this oil helps you […]

Author Archives: hx_seo

In modern composite manufacturing, the efficiency of demolding and product quality impact a company’s competitiveness. Polyvinyl alcohol (PVA) release agent is an innovative solution that many companies now prefer. It boosts demolding efficiency and ensures a smooth, defect-free surface, meeting the demand for high-quality products. As environmental concerns grow, PVA release agents are popular for […]

Choose from these best 10 Concrete Releasing Agents for 2026: Meiyahg Concrete Releasing Agents, Alumi-Con, Sika AG Eco Release, Master Builders Solutions Form Release, Castor Oil, Isopropyl Alcohol, Bio Strip WB Concentrate, Form Shield Water-Based, PavePro Blue, and Antique Release Powder. Pick the right concrete releasing agent for your job and what people need. […]

In the world of high-volume injection molding, perfection is the goal, and consistency is king. Your process is dialed in, your cycle times are optimized, and production is running smoothly. Then, you see it: a newly ejected part marred by a subtle but critical surface flaw. It’s a frustrating moment that can quickly escalate into […]

I often wonder which mold release agent is best for B2B use, particularly when considering Water-Based vs. Solvent-Based Mold Release Agents. Water-based agents are now the most used, accounting for 52.8% of sales in 2023. These agents utilize water to carry the active components, while solvent-based agents rely on chemical solvents instead. The differences between water-based and solvent-based […]

I know picking the right mold release agent is important. It can change how things turn out in car-making. When I use carbon fiber body parts or battery cases, I want fast curing. I need it to cure at low heat, between 80 and 120°C. I also think about the environment. Water-based choices are better […]

You use mold release agents for wind turbine blades. They help the blades come out of the mold easily. The blades do not get damaged. These agents stop problems like sticking or surface flaws. Choosing the right agent is important. Using it the right way helps you get better results. It also saves time and […]

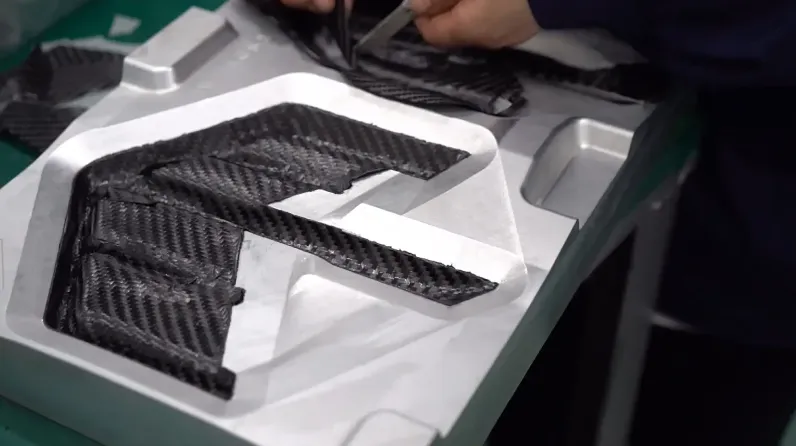

When you work with carbon fiber, it’s crucial to use the demolding technique for carbon fiber frames to avoid damaging the material when removing it from the mold. The best way to safely remove carbon fiber frames is to use safety gear and proceed slowly. Always wear eye protection and gloves before you start. Safety […]

Choosing the best shoe sole release agent is important for your factory. You should see how the release agent works with your materials. Make sure it matches what your factory needs. Good agents help you get better products and save money. Eco-friendly choices are good for the environment. Test new agents step by step in […]

The rubber injection molding process in the factory follows a series of well-defined steps. This process transforms raw rubber into finished components. Careful attention to each phase of the rubber injection molding process in the factory is essential to produce strong and precise products. Selecting the appropriate material is crucial, as is properly setting up […]