Details About Bulk Magnesium Alloy Die Casting Release Agent

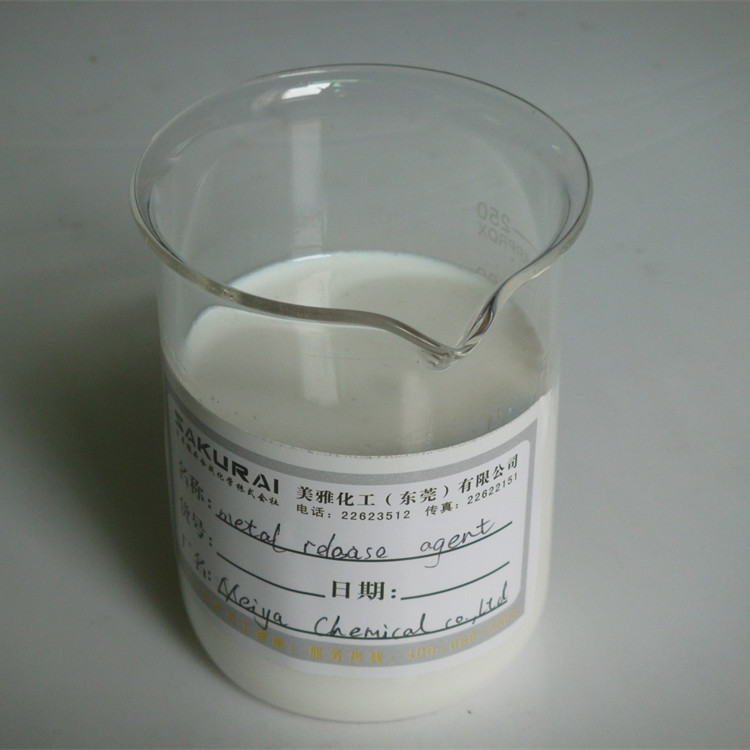

Name: Magnesium Die Casting Release Agent

Brand: SAKURAI

Model: MK-TF

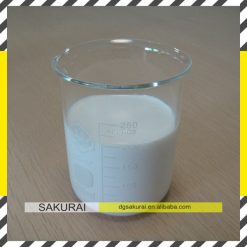

Appearance: Milky white liquid

Solubility: Water-based

Packing: 25KG/200KG

Supply for: Magnesium die casting factory

Process: General die casting parts

Performance: None carbon deposition, white and bright surface finished and easy to release from the dies.

Usage: Auto or Manual spray

MOQ: 200 KGs after sample trial

Application

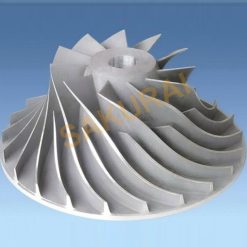

Sakurai MK-TF mold release agents are applied for magnesium alloy die casting, the thickness of 0.5mm or more large of magnesium, such as precision electronic parts, computer shell, aviation products, cellphone medium plate die casting.

Product Features

1.Stable temperature performance – using high-temperature film forming materials, high-temperature mold surface with good adhesion, in a mold temperature up to 320 ℃ operating temperature. Not in the mold and the casting surface carbon or oxide.

2. Excellent lubricating properties – with temperature lubricant, film uniformity, do not build up at a high temperature to provide excellent lubrication, the shaped cavity filled with molten metal Tangshan Li. While substantially reducing the friction between the mold and the casting, making the products more smooth release and extended tool life.

3.Good heat dissipation and insulation properties – When an aqueous solution containing release agent mold surface when exposed to high temperature, moisture evaporates quickly remove excess heat to ensure that mold in the design temperatures; simultaneously release agent will be attached to the surface of the mold lubricating insulation film, high-temperature red rinse, ensuring magnesium alloy melting and rapid cooling soup will not fill smoothly shaped cavity, after the separation, the casting surface does not affect the porosity and compaction.

4. Low odor properties – smell is very soft, non-irritating odor in operation produces no oil mist generation, to maintain a good environment for the workshop.

5. Excellent corrosion resistance – magnesium alloy products have excellent oxidation corrosion protection, casting a clear outline, smooth surface does not affect the coating.

6. Good safety performance– with a high degree of biodegradability, does not contain any hazardous ingredients.

7. Good cleaning performance– the mold surface is almost no residue, cleaning and maintenance is simple, the product surface smooth, free cleaning.