Main Properties Of Internal Release Agent

- Supply for: Carbon fiber and epoxy resin products factory etc.

- Process: Hand lay-up, Mould pressing, Winding, Vacuum pouring, Pultrusion

- Performance: Fast drying, no oily residues, stable release performance and no stick on the mold.

- Usage: Auto or Manual spray.

- MOQ: 25 Liters after sample trial

Application Of Internal Release Agent

Sakurai MK-600 is an internal addition release agent for carbon fiber composite materials, such as carbon fiber plate, sheet, fishing rod, golf clubs, bike rack, shaft surface, tennis rackets, and other epoxy resin molding releases.

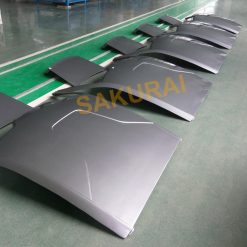

As shown in the picture, the customer purchased our release agent for the production of carbon fiber trekking poles. During the production process, our company’s release agent is sprayed inside the mold. It can form a smooth coating on the surface of the product to ensure integrity and aesthetics of the product. Our product is a food grade release agent, which will not cause any pollution to the product and the human body.

Product Features

1.Good stability – At the mold surface can be rapidly formed, the mold surface with good adhesion, no accumulation in the mold and the product surface.

2.Excellent lubrication – Film uniformity, smooth filling the slurry into the cavity, while greatly reducing friction between the molded product, making the product more smoothly stripping and extend tool life.

3. Very low odor performance – Smell very gentle, non-strong odor in operation, maintain good environmental workshop.

4. Good safety performance – Does not contain any harmful ingredients, the human body without harm.

5. Good cleaning performance – Mold surface is almost no residue, cleaning and maintenance is simple, does not affect the smooth surface coating products.