The advantage of using a PVA release agent is greatly improves work efficiency. The traditional way of using paste mold releases wax, for large-mold applications, it needs to brush more than 8 times to cover the mold fully, counting each polishing time, labor costs are very high. However, the PVA release agent is only needs to be sprayed with 2 layers on the basis of two layers of mold release wax coat, which can achieve smooth release without polishing demand. The combination of using mold release wax and PVA release agent is the most effective demolding option.

Applying the PVA release agent

- Pre-treatment of the mold, sandblasting, or use our recommended cleaning agent to clean the mold.

- It can be used within a range of 20~180℃ by spraying or wiping. The recommended usage is spraying. We recommend heating the mold to 50℃ before using this release agent. Or it takes 5-10 minutes for drying under room temperature without heating mold.

- Mold surface coating at least 2-3 times for new mold and the cleaned mold, and each time after spraying, must wait until the surface to dry thoroughly before next coating.

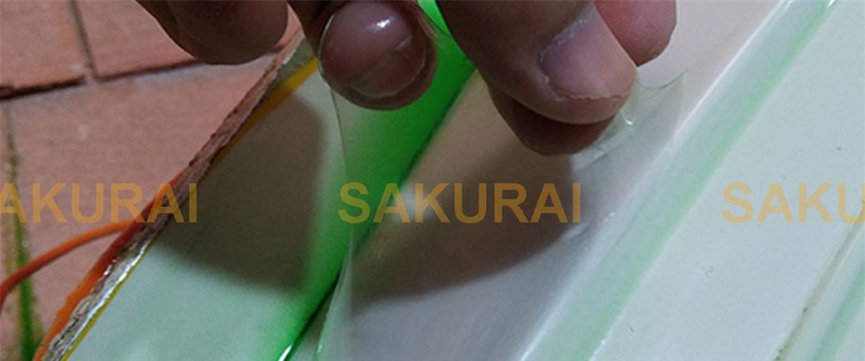

- After the mold is completely coated, need to wait for 30 minutes at room temperature before start production. (Mold surface is dry and non-stick, then you can use)

- Recommended to spray one fresh layer of release agent after every demoulding, to ensure good demoulding performance.