Brand: SAKURAI

Model: MK-TG

Appearance: Transparent Red-brown Liquid Release Agent

Solubility: Oil-based and water-based

Packing: 20KG/170KG

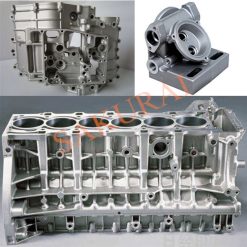

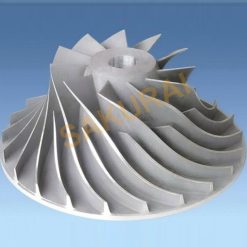

Supply for: Suitable for all kinds of zinc alloy fittings and various zinc alloy parts with high complex surface requirements

Process: General Zinc alloy die casting parts,such as Zipper,Fastener,Button

Performance: None carbon deposition, good lubrication and stable release performance

Usage: Auto or Manual spray

MOQ: 200 KGs after sample trial

Application

MK-TG is suitable for general and complicated Zinc alloy fittings die casting by hot chamber and cold chamber machine, such as lamp fittings and zipper, fastener,button.

Product Features

1.No carbon deposition performance

There will be no carbon deposition or oxide scale on the mould or casting surface, do not affect the subsequent surface treatment such as electroplating ,flame plating, etc.

2.Excellent demolding performance

Spray die casting mould release to the mould surface then effective components immediately form dense membrane, the membrane in the injection process effectively prevent die-casting products and the mould

glue together.

3.Good cooling effect

Using the die-casting mould release agent and setting the mould temperature in 150-200 ℃, the mould will not cracks caused by heat and cold stress, which shortens the work cycle.

4.High temperature resistant and excellent lubricating performance

Die casting mold release agent film uniformity, not accumulation, casting surface bright and no splash. Die releasing agent for high temperature mold surface has good adhesion, can in the mold temperature up to

200DEG C under the condition of operation.

5.Cleaner & safer environments

Die-casting release agent is non-toxic, no burning, no corrosion, no chemical reaction, and in the useing process there will be no harmful smoke or smell, you can have a cleaner & safer environment

6.Clean and smooth castings

No residue on the casting surface, easy for clean and maintenance.