I see carbon fiber is changing many industries. It is strong and light. It does not rust easily. Mold factories help make good carbon fiber parts. These parts are used in planes, cars, and sports gear. The market is getting bigger:

- In 2024, the global carbon fiber market was $5,747.9 million.

- By 2030, experts think it will be $10,683.3 million.

I want to explain how the carbon fiber molding process works. I will also tell you why mold design is important for strong and exact parts.

Overview

What Is Carbon Fiber Molding?

When I do carbon fiber molding, I use prepregs. These are special sheets with carbon fibers and resin. I cut the sheets and put them in a mold. I make sure to place each layer carefully. The way I set the fibers changes how strong the part is. After I finish, I close the mold and put it in an autoclave. The autoclave uses heat and pressure to make the part hard and light. Mold factories help me get the right shape every time. They use exact molds and check the process. This makes sure each part is made well.

Key Benefits

Carbon fiber molding gives me many good things over old materials.

- Great material properties: The parts I make are lighter and stronger than metal.

- Better fuel use and performance: Lighter parts help vehicles save fuel and go faster.

- Can make many parts: Big companies like BMW use carbon fiber in cars, so it works for lots of products.

- Replaces other materials: In sports, carbon fiber takes the place of heavier parts, making gear lighter and stronger.

- Better performance: Carbon fiber is strong, so parts break less, even when used a lot.

Common Applications

I see carbon fiber molding used in many areas. Mold factories help make parts for these jobs:

| Industry | Typical Applications |

|---|---|

| Sports and Recreation | Tennis rackets, golf clubs, bikes, racing boats |

| Renewable Energy | Wind turbine blades, solar panel parts |

| Construction | Concrete support, bridges, tunnels |

| Marine | Boat hulls, masts, rigging |

| Healthcare | Prosthetics, bone implants, X-ray and MRI equipment |

Aviation and UAVs also use carbon fiber for strong, light parts that last in tough places. Mold factories make sure each part fits right and works well.

Molding Methods

Modern factories use several advanced methods to shape carbon fiber into strong, lightweight parts. You can choose the best technique based on your needs for speed, quality, and cost.

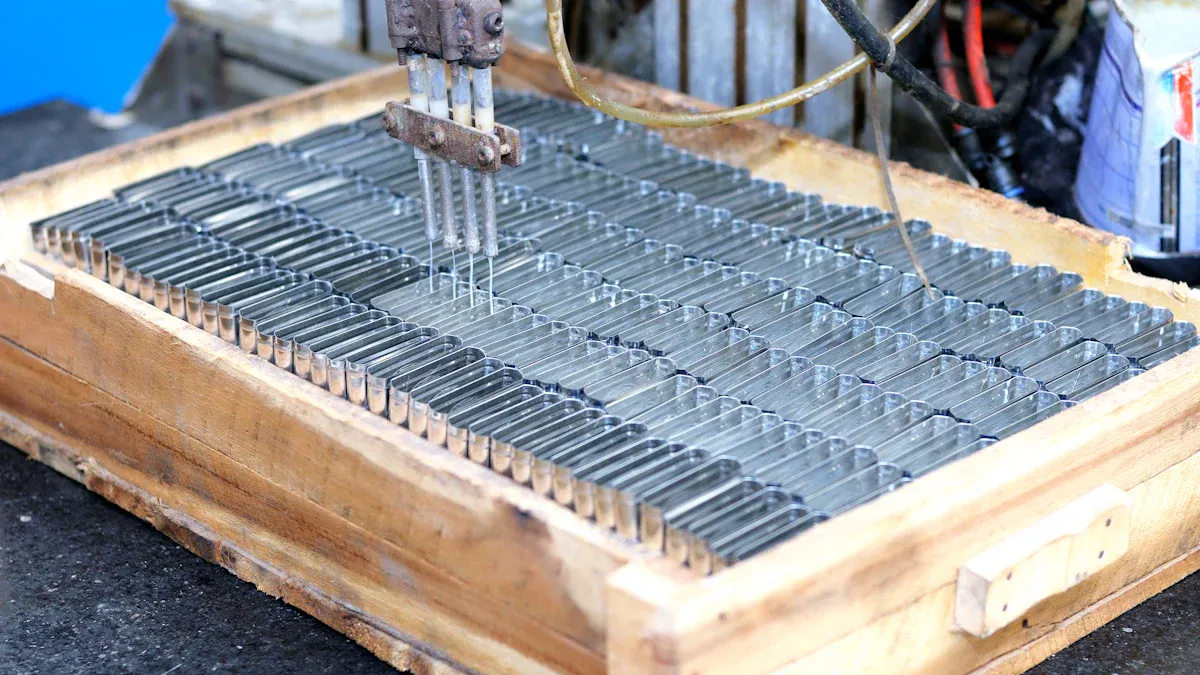

Compression Molding

You use compression molding when you want high-volume production and complex shapes. This method presses carbon fiber and resin between heated molds.

- Optimized curing processes make compression molding very efficient.

- Cycle times are short, often around two minutes.

- Efficiency can improve by over 247%, and energy use drops by more than a third with the right process.

- You get consistent results and save money on labor and energy.

Tip: Compression molding works best for mass production of automotive and industrial parts.

Continuous Molding

Continuous molding helps you produce long, uniform carbon fiber components. You feed material into the machine without stopping, which boosts throughput and reduces waste.

| Advantage | Continuous Molding (CCM) | Batch Processes |

|---|---|---|

| Production Efficiency | High | Lower |

| Material Waste | Minimal | Higher |

| Component Consistency | High | Variable |

| Automation Potential | High | Limited |

| Cost-Effectiveness | High | Lower |

You get large quantities of parts with steady quality. Fiber alignment improves mechanical properties, and you waste less material.

Resin Infusion

Resin infusion lets you make lightweight, strong parts. You lay dry carbon fiber in a mold and draw resin through it using vacuum pressure. This method gives you good control over fiber placement and resin flow. You can create complex shapes with fewer defects.

Injection Molding

You use injection molding for small, detailed carbon fiber parts. You inject resin and chopped fibers into a mold at high speed.

- Injection speeds range from one to five seconds.

- You can produce up to 2,000 small parts per hour with multi-cavity molds.

This method works well for electronics, consumer goods, and automotive clips.

BMC Injection

Bulk Molding Compound (BMC) injection uses a mix of resin and short carbon fibers. You inject this compound into molds quickly. BMC injection is ideal for high-volume production of small, precise components.

Resin Transfer Molding

Resin Transfer Molding (RTM) helps you make parts with excellent structural integrity. You place dry fiber preforms in a closed mold and inject resin under pressure.

- RTM ensures fibers are fully soaked with resin, boosting strength.

- You minimize voids, which keeps mechanical properties high.

- Proper curing prevents warping and internal stress.

You can create complex shapes with consistent quality, making RTM popular for aerospace and high-performance uses.

The Carbon Fiber Molding Process in Molding Factory relies on these methods to deliver efficient, accurate, and cost-effective results for many industries.

Carbon Fiber Molding Process Steps

Design and Material Selection

You start the Carbon Fiber Molding Process in Molding Factory by focusing on design and material selection. The right choices here set the stage for strong, lightweight parts. You look at the shape, thickness, and surface finish you want. You also consider how the part will be used and what stresses it will face.

| Criteria | Details |

|---|---|

| Material Thickness | Ranges from .040” to ½”; sandwich construction for lighter, stiffer parts |

| Corner Radius | 1/8″ or larger to reduce stress |

| Shape | Matches mold shape; can be contoured |

| Dimensional Tolerance | +.010” |

| Surface Finish | Class A, gel coated, painted, or other coatings |

| Shrinkage | .0005 in/in |

| Electrical Properties | Conductive |

| Fire Retardant | Resins available for fire safety |

| Corrosion Resistance | Resins for harsh chemicals |

| Mold Types | Male or female molds; female molds give smooth exteriors |

| Mold Material | Composite, metal-filled epoxy, aluminum, or steel |

You select materials that offer high strength, durability, and resistance to wear. Good machinability and dimensional stability help you achieve precise results. These choices improve the efficiency and quality of the Carbon Fiber Molding Process in Molding Factory.

Mold Preparation

Next, you prepare the mold. Mold preparation is critical for part quality and production speed. You choose the right mold type based on your process:

| Mold Type | Properties |

|---|---|

| Carbon Fiber Autoclave Molds | Withstand high temperature and pressure; ensure dense, strong parts |

| Carbon Fiber Compression Molds | Enable rapid forming and high production efficiency |

| Composite Carbon Fiber Molds | Combine materials for extra durability |

You clean the mold and apply a release agent. This step prevents the part from sticking and keeps the surface smooth. You may also use coatings like gelcoat to improve durability and surface finish. Proper mold preparation reduces defects and helps you achieve a flawless result.

Lay-Up and Resin Application

You move to the lay-up and resin application stage. Here, you place carbon fiber sheets or preforms into the mold. You apply resin evenly to ensure every fiber gets coated. Uniform resin distribution is key for strength and structural integrity.

| Best Practice | Description |

|---|---|

| Uniform Resin Distribution | Use brushes, rollers, or squeegees for even application |

| Vacuum Bagging | Removes air pockets and compresses layers for strong bonding |

| Proper Mold Preparation | Clean surfaces prevent imperfections and adhesion issues |

You often use vacuum bagging to remove air bubbles and compress the layers. This step boosts the mechanical properties of the finished part. Careful lay-up and resin application help you avoid weak spots and ensure the Carbon Fiber Molding Process in Molding Factory delivers reliable results.

Shaping and Curing

Now, you shape and cure the part. You close the mold and apply pressure to form the final geometry. You control the temperature and pressure to get the best results. For most carbon fiber parts, you cure at temperatures between 112°C and 140°C. Pressures around 0.4 MPa work best for strong, stable parts.

Note: Higher curing temperatures can improve strength, but too much heat or pressure can reduce performance.

You monitor the process closely. You switch from displacement control to pressure control to manage resin flow and shrinkage. This careful approach ensures the part reaches the right thickness and fiber volume. Shaping and curing are vital steps in the Carbon Fiber Molding Process in Molding Factory because they lock in the part’s strength and shape.

Demolding and Finishing

After curing, you open the mold and remove the finished part. You clean and inspect the surface. You may apply a clear coat or sand the surface to a fine finish. These steps improve appearance and protect the part from UV and wear.

- Start with a clean, glossy mold.

- Wax and spray the mold with PVA for easy release.

- Paint the mold with resin before lay-up.

- Vacuum bag the part, keeping pressure within safe limits.

- After demolding, apply a clear coat and sand to a smooth finish.

Applying surface coatings like gelcoat can boost durability and reduce roughness. You check for defects and make sure the part meets all quality standards. Good finishing ensures the Carbon Fiber Molding Process in Molding Factory produces parts that look great and last long.

Quality and Advancements

Inspection and Testing

You play a key role in making sure every carbon fiber part meets strict standards. Factories use many inspection and testing methods to catch defects early and keep quality high.

- You rely on a Quality Management System (QMS) to guide every step.

- You monitor production with process control tools.

- You train employees to follow procedures and spot problems.

- You check supplier materials before they enter the factory.

- You test and inspect products regularly.

- You look for ways to improve with continuous assessment.

You use advanced tools to find defects inside and outside the parts.

- X-ray and CT scanning help you see inside for voids or fiber misalignment.

- Thermography shows temperature changes that reveal hidden flaws.

- Visual inspection lets you spot surface scratches or resin runs.

- Destructive testing checks how strong a part is by pushing it to failure.

You also use ultrasonic testing, radiography, eddy current testing, and shearography. These methods help you find cracks, delaminations, and other problems.

Here is a table showing common defects and their importance:

| Defect Type | Criticality Ranking |

|---|---|

| Fiber breakage | Most critical |

| Delaminations | High |

| Matrix cracks | Moderate |

| Voids and porosity | Lower |

| Fiber misalignment | Least critical |

| Resin variations | Least critical |

You use these tools and steps to make sure the Carbon Fiber Molding Process in Molding Factory produces reliable parts.

Automation

You see more factories using automation to boost efficiency and quality. AI-driven machines help you keep production steady and spot problems before they happen.

- Automation improves consistency and reduces mistakes.

- Predictive maintenance keeps machines running smoothly.

- Industry 4.0 technologies change how you work, making everything faster and smarter.

Automated processes save energy. You can cut energy use by 75% to over 90% compared to older methods.

- Manual autoclave curing uses much more energy than automated systems.

- Out-of-autoclave processes need less power and work faster.

You help your factory stay ahead by using smart robots and sensors. Automation makes the Carbon Fiber Molding Process in Molding Factory more efficient and cost-effective.

Sustainability

You help protect the environment by supporting new sustainability efforts. Carbon fiber production creates a lot of greenhouse gases, but you can lower emissions by using renewable energy.

- Switching from coal to renewables can cut emissions by up to 62%.

- Using carbon fiber in cars and planes saves fuel and reduces CO2 over time.

Factories recycle and upcycle waste. Elevated Materials has kept 200,000 pounds of carbon fiber out of landfills.

- Partnerships like Toray and Elevated Materials aim for net zero emissions by 2050.

- These efforts focus on reducing waste, pollution, and resource use.

You make a difference by choosing greener materials and better processes. Your work helps the industry move toward a cleaner future.

You have seen how modern factories use advanced methods like compression molding, resin transfer molding, and continuous molding to shape carbon fiber. Each step, from design to finishing, needs careful control and skilled labor. You get strong, lightweight parts because carbon fiber is 75% lighter than steel but up to 12 times stronger. Factories use AI, robotics, and sustainable materials to boost quality and save energy.

You can expect even more growth as industries demand lighter, eco-friendly products. Explore more about carbon fiber to see how technology shapes the future.

FAQ

What makes carbon fiber parts so strong and light?

You get strength from the way carbon fibers align in the mold. The resin holds the fibers together. This combination creates parts that are much lighter than steel but can handle heavy loads.

How do you keep defects out of carbon fiber parts?

You use quality checks like X-rays, CT scans, and visual inspections. These tools help you find cracks, voids, or misaligned fibers before the parts leave the factory.

Can you recycle carbon fiber parts?

Yes, you can recycle carbon fiber. Factories use special processes to recover fibers from old parts. Recycled fibers help you make new products and reduce waste.

Why do factories use automation in carbon fiber molding?

Automation helps you work faster and make fewer mistakes. Robots and smart machines place fibers, mix resin, and control curing. This keeps your parts consistent and saves energy.