When you work with carbon fiber, it’s crucial to use the demolding technique for carbon fiber frames to avoid damaging the material when removing it from the mold. The best way to safely remove carbon fiber frames is to use safety gear and proceed slowly. Always wear eye protection and gloves before you start. Safety is important because carbon fiber can break or create sharp edges. Be patient to ensure your project remains safe and looks good.

Safety and Preparation

You must get ready and think about safety before you demold your carbon fiber frame. Doing the right things now helps you stay safe and keeps your frame from getting ruined.

Personal Protective Equipment

Always wear personal protective equipment when you work with epoxy resin and carbon fiber. Sharp edges can cut you, and resin can bother your skin. Here is a simple list of what you should use:

| Type of Protection | Recommendation |

|---|---|

| Eye Protection | Wear eye protection when you measure, mix, or laminate with epoxy resin |

| Gloves | Wear nitrile gloves (not latex) when touching carbon fiber because of sharp edges |

Tip: Never forget to use safety gear. Good safety habits stop injuries and help keep your area tidy.

Mold Release Wax Application

Using the right release film makes demolding easier. You should pick a wax made for release systems. Here are some easy tips for putting on release film:

| Method/Tip | Description |

|---|---|

| Application Technique | Rub wax in small spots with a clean rag. Cover every part. |

| Coating Process | Put on more than one coat. Wait at least 15 minutes between each coat. |

| Liquid Wax Use | Thin liquid wax is quick but not as good for new molds. |

| Wax Selection | Use high-temperature wax for the best results. |

| PVA and Wax | You can put PVA on top of wax, but not wax on PVA. |

You can also use silicone-based or fluoropolymer release film for some projects. These work well for frames in cars or planes.

Full Cure Check

Make sure the resin is fully cured before you take off your frame. This step keeps you safe and helps your frame look good. Here is how you can check:

- Use a hardness tester like Shore D or Barcol 934 to test the surface.

- Wait until the part cools to room temperature after curing. This stops extra stress and helps the release film work better.

- Check for places where the release film has come off or lifted. If you see any, fix them before you start demolding.

If you use pre-preg, follow the rules for curing times. Fast-cure prepreg needs just a few minutes with high heat. Standard prepreg takes hours. Always check if your vacuum bagging materials and foam work with your release film.

Note: Take your time when cooling and checking the cure. This helps you avoid stuck parts and bad surfaces.

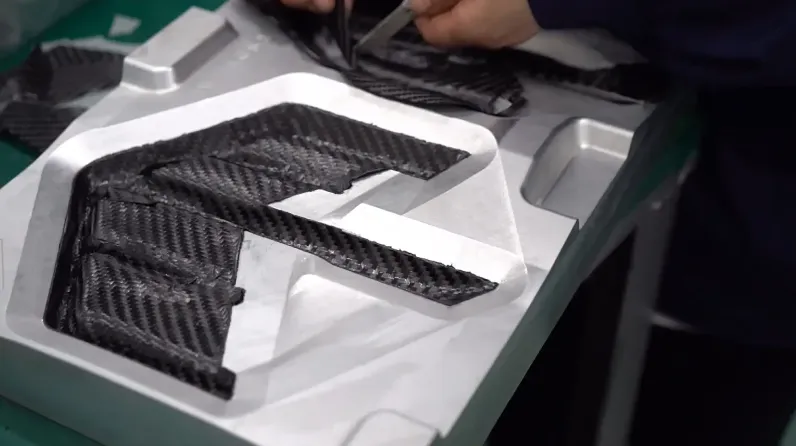

The Demolding Technique for Carbon Fiber Frames

When you reach the stage of removing your frame from the mold, you want to use the demolding technique for carbon fiber frames that keeps your hard work safe. This part of the process can make or break your project. You need the right tools, a gentle touch, and a clear plan. Let’s walk through each step together.

Tool Selection

Choosing the right tools makes the demolding technique for carbon fiber frames much easier. You want to avoid scratches, chips, or cracks. Here are some tools you should have ready:

| Tool Type | Purpose |

|---|---|

| Sharp Knife/Scalpel | Cutting release film and trimming edges |

| Flat H-Frame | Supporting the frame during removal |

| Rubber/Nylon Pry Bar | Gently prying at parting lines without damage |

| Ejector Pins | Pushing flat areas out of the mold |

| Air Compressor | Blowing air through reserved channels for release |

| Vibration Tool | Loosening complex parts with gentle vibration |

You can also use a split mold if your frame has two pieces. This lets you separate the mold without forcing the part. Always check that your release film is still in place before you start. If you see any spots where it has lifted, fix them first.

Step-by-Step Demolding Process for Carbon Fiber Frames

You want to follow a careful process for the demolding technique for carbon fiber frames. Rushing can ruin your frame or leave marks on the surface. Here’s a simple step-by-step guide:

- Make sure the resin is fully cured and the release film is intact.

- Open the mold slowly. If you have a two-piece mold, loosen the bolts or clamps a little at a time.

- Use a rubber or nylon pry bar at the parting lines. Work around the edge, lifting gently. If the part sticks, try using ejector pins on flat areas.

- For tough spots, use air pressure. Blow air into the reserved channels to help separate the frame from the mold. This keeps the release film from tearing.

- If you have a complex shape, use a vibration tool. A few seconds of gentle vibration can help the release film do its job.

- Once the frame starts to move, support it with a flat h-frame. This keeps it from bending or twisting.

- Lift the frame out of the mold. Check for any spots where the release film is stuck. If you find any, stop and work them loose with your fingers or a soft tool.

- Inspect the frame for defects. Look for surface holes, rough spots, or places where the release film did not work.

- If you see any problems, fix them before moving on.

Cutting Excess Material

After you finish demolding, you will see extra material around the edges. You need to trim this off to get a clean, strong frame. The demolding technique for carbon fiber frames includes careful cutting to avoid splintering or cracks.

Here’s how you can cut excess material safely:

- Measure the frame and mark where you need to cut. Use a metallic Sharpie for clear lines.

- Wrap tape around the area you plan to cut. This keeps the release film from lifting and stops splinters.

- Use a hacksaw with a fine blade. This gives you a smooth cut and protects the release film.

- Place a tube cutting guide on the frame. Secure it in a vice for extra safety.

- Cut slowly. Let the saw do the work. Don’t force it.

- Use backing material like wood or foam under the cut. This stops blowout on the backside.

- After cutting, sand the edges with fine sandpaper. This smooths out any rough spots and keeps the release film from peeling.

- When you put the frame back together, use a torque wrench. This keeps you from over-tightening and damaging the release film.

Pro tip: Prepare all your tools before you start. This makes the demolding technique for carbon fiber frames smoother and safer.

Demolding Troubleshooting

Stuck Part Solutions

Sometimes, you might find your carbon fiber frame stuck in the mold. This can feel frustrating, but you have options. First, check if the release film covers every part of the mold. If you see gaps or thin spots, the frame can stick. Always use enough release film and make sure it sits flat. If you notice the frame will not budge, try gentle air pressure. Blow air into the mold’s channels. This helps the release film separate from the frame. You can also use a rubber or nylon pry bar. Work slowly around the edges. Never use metal tools because they can scratch the release film and damage your frame.

If you still have trouble, look at your release systems. Sometimes, the type of release agent or how often you apply it makes a difference. Try a different release agent or add more coats next time. A smooth mold surface helps too. Polish the mold before you start. This lets the release film work better and stops the frame from sticking. For demoulding carbon fibre parts, patience is key. Rushing can tear the release film or deform your frame.

Preventing Mold Damage

You want your mold to last for many projects. Keeping it safe during demolding starts with good habits. Clean your workspace before you begin. Dirt or dust can get trapped under the release film and scratch the mold. Work in a room where you can control the temperature and humidity. This helps the release film cure right and makes demolding easier.

Here’s a quick table with tips to protect your mold:

| Preventative Measure | Description |

|---|---|

| Maintain Cleanliness | Keep the workspace clean to avoid contamination of the carbon fiber and resin. |

| Work in a Controlled Environment | Temperature and humidity can affect the curing process. Work in a controlled environment to achieve the best results. |

| Use Release Agent | Apply a mold release agent to prevent the carbon fiber from sticking to the mold. Ensure an even coating for easy part removal. |

Always check the release film before you start demolding. If you see any lifted spots, fix them right away. When you remove the frame, support it with both hands. This stops bending and keeps the release film from tearing. Let the frame cool at a steady rate. Quick changes in temperature can warp the frame or damage the release film. Make sure your mold is strong enough for the job. A rigid mold keeps the release film tight and helps you get a clean release every time.

Tip: A little extra care with the release film and your mold pays off in better frames and fewer problems.

Common Demolding Mistakes

When you work with carbon fiber frames, it’s easy to make mistakes during demolding. These mistakes can ruin your hard work or even hurt you. Let’s look at the most common problems and how you can avoid them.

Skipping Safety Steps

You might feel tempted to skip safety gear, especially if you’re in a hurry. This is never a good idea. Carbon fiber edges can be sharp, and resin can irritate your skin. Always wear gloves and eye protection. If you forget these steps, you risk cuts, burns, or even chemical exposure. Safety gear also keeps your workspace clean and helps you focus on the job.

Tip: Make safety your first step every time. It’s much easier to prevent an injury than to treat one.

Rushing the Process

Trying to speed up demolding can cause big problems. Here’s what can happen if you rush:

- You might damage the carbon fiber frame.

- The mold itself can break or crack.

- The final product may lose its strength and not work as it should.

If you pull the frame out before it cools or before the resin cures, you can cause warping or cracks. Always let the frame cool to room temperature. Check that the release systems are still working before you start. Take your time and use gentle force. Patience helps you get a clean, strong frame every time.

Incorrect Tool Use

Using the wrong tools can scratch or chip your frame. Metal screwdrivers or hard steel tools can damage both the mold and the part. You should always use rubber or nylon pry bars, soft ejector pins, or air pressure for separation. These tools protect your frame and help the release systems do their job. If you use the right tools, you’ll avoid most problems and keep your mold in good shape for future projects.

Remember: The right tools and a careful approach make demolding safe and easy.

Best Practices for Carbon Fibre Moulding

Quick-Reference Checklist

You want your carbon fibre moulding projects to go well every time. Use this simple checklist before and after demolding to keep your work safe and neat:

| Step | What to Do |

|---|---|

| Eye Protection | Always put on safety glasses before you start any moulding or demolding. |

| Nitrile Gloves | Wear nitrile gloves when you touch resin or carbon fibre. |

| Ventilation | Work in a place with good airflow. Use a vapor mask if you need it. |

| Protective Gloves | Use thicker gloves when you take off sharp carbon fibre parts. |

| Respirator | Wear a respirator when you cut or sand cured carbon fibre. |

| Release Systems | Put high-quality release agents on your mold before you start moulding. |

| Weave Selection | Pick twill weave for flexibility or plain weave for a smooth finish. |

| Epoxy Resin | Choose a strong epoxy resin for better durability. |

| Vacuum Bagging | Make sure you vacuum bag the right way to stop defects. |

| Temperature and Pressure | Control both during moulding to stop warping or bubbles. |

| Flash Removal | After demolding, trim extra material with sandpaper or a grinding wheel. |

| Surface Cleaning | Wipe the frame with alcohol or a special solvent to clean off residue. |

| Defect Inspection | Look for flaws with your eyes, or use tools like ultrasound or X-ray. |

| Defect Repair | Fix small flaws with resin or filler. Scrap the part if damage is too bad. |

Tip: Keep this checklist close by in your workspace. It helps you remember each step for safe and easy carbon fibre moulding.

Maintenance Tips

Taking care of your moulding tools and molds helps your projects go smoothly. Here are some easy ways to make your equipment last longer:

- Keep a logbook. Write down every time you clean or fix your tools. This helps you find problems early.

- Check ejector pins and moving parts. Make sure nothing is bent and everything moves easily. Add a little lubricant if needed.

- Look at each mold part for wear. Replace seals if they look old. Clean out cooling channels to stop rust or scale.

- Strip off old layers of release agent after several uses. Start fresh with new coats to keep your release systems working well.

- Set a schedule for maintenance. You can base this on how often you use your tools or how many frames you make.

You now understand how to demold carbon fiber frames safely. Always wear safety gear before you start. Follow each step slowly and carefully. Check your release systems before you begin. Here’s what experts do:

| Key Takeaway | Details |

|---|---|

| Handling Care | Gentle demolding stops damage to the frame and mold. |

| Cost Efficiency | PLA molds can save a lot of money. |

| Heating Efficiency | Polymer molds heat up fast and help make better parts. |

- Check your frames often and fix problems quickly.

- Good airflow and curing help keep you safe.

- Clean your tools and molds for the best results.

FAQ

What should I do if my carbon fiber frame sticks to the mold?

Try using gentle air pressure or a rubber pry bar at the edges. Check if you applied enough release agent before starting. If you still have trouble, review your release systems for better results next time.

How can I tell if the resin is fully cured before demolding?

Touch the surface and use a hardness tester if you have one. The frame should feel solid and cool to the touch. If it feels soft or sticky, wait longer before trying to remove it.

Why is it important to let the mold cool before demolding?

Letting the mold cool helps prevent the frame from warping or cracking. If you rush this step, you might damage the part or make it stick to the mold.

What tools work best for safe demolding?

Use rubber or nylon pry bars, soft ejector pins, and sometimes compressed air. Avoid metal tools because they can scratch or chip your frame.

How do I clean my frame after demolding?

Wipe the frame with alcohol or a special solvent to remove leftover release agent or oils. This keeps your frame looking good and ready for the next steps.