The rubber injection molding process in the factory follows a series of well-defined steps. This process transforms raw rubber into finished components. Careful attention to each phase of the rubber injection molding process in the factory is essential to produce strong and precise products. Selecting the appropriate material is crucial, as is properly setting up the machinery. Controlling the mold throughout the rubber injection molding process in the factory ensures high-quality results. Meiyahg, a mold release agent manufacturer, produces agents that make it easier to remove parts from molds. However, there are several common challenges in the rubber injection molding process in the factory, such as choosing the right material, designing the mold, and maintaining tight tolerances. The table below outlines some typical issues you might encounter:

| Challenge | Description |

|---|---|

| Material Selection and Compatibility | Picking the wrong rubber can cause defects or weak parts. |

| Tooling Design Complexity | A bad mold design can trap air or cause uneven curing. |

| Maintaining Dimensional Tolerances | Rubber can change size, so it is hard to keep exact measurements. |

| Curing and Cycle Time Management | Curing time changes with rubber type and part thickness. |

Rubber Molding Process Overview

What Is Rubber Injection Molding?

The rubber molding process shapes raw rubber into finished parts. Factories use this process to make strong and reliable products. Machines heat and push rubber into molds. This method is not like other ways because it gives more control over shape and quality. You can make complex parts with tight tolerances using liquid silicone injection molding. This makes the process good for parts that need to last and handle tough jobs.

The rubber molding process has several main steps. The table below shows each step and what happens during liquid silicone injection molding:

| Stage | Description |

|---|---|

| Material Preparation | You get the rubber ready and mix in additives for the right properties. |

| Melt Unit | The rubber melts and stays thick and flowy. |

| Mold Setup | The mold is clamped shut to make a space for injection. |

| Injection | Heated rubber is pushed into the mold space with high pressure. |

| Vulcanization | The rubber cures with heat and pressure and becomes solid. |

| Cooling and Ejection | The mold cools, and the solid rubber part comes out. |

| Deflashing | Extra rubber is trimmed off the finished part. |

Tip: Meiyahg makes mold release agents for the rubber injection molding process. These agents help you take parts out of molds easily and keep production moving.

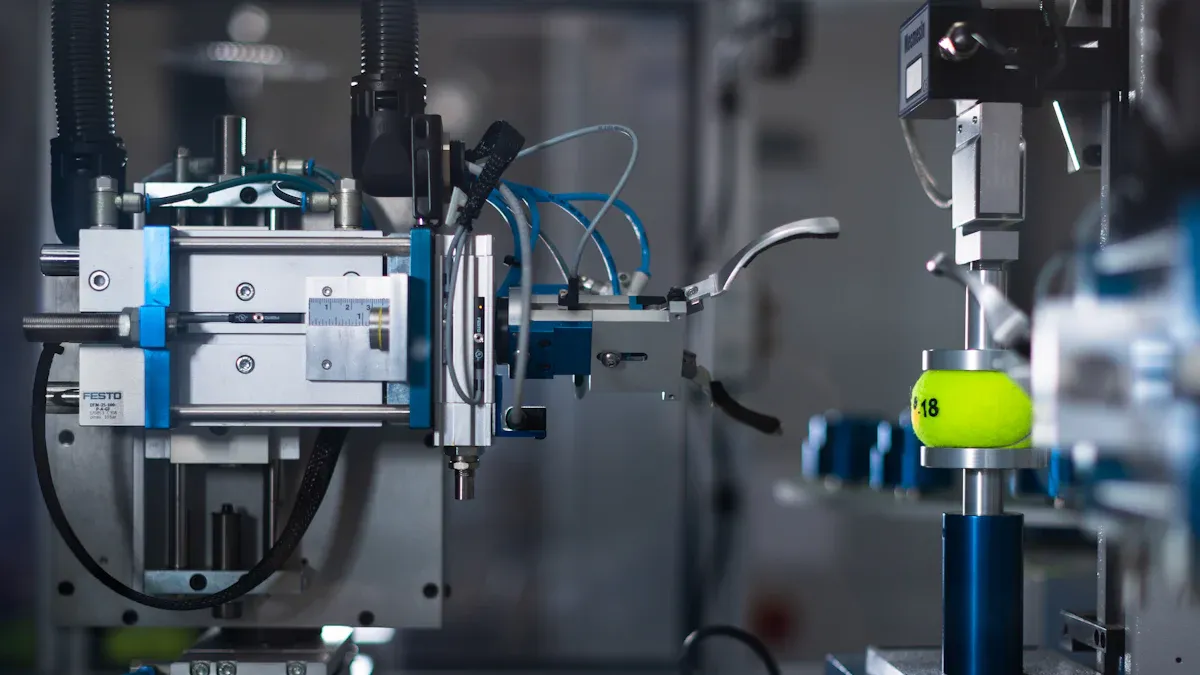

Industrial Uses

Many industries use the rubber molding process. Factories use liquid silicone injection molding to make car seals, medical tools, and electrical parts. This process is fast and good for making lots of parts. You can count on liquid silicone injection molding for strong and flexible products. The rubber molding process also cuts down on waste, which saves money. Automated systems in liquid silicone injection molding check quality at every step, so results stay the same. This process works well for both small and big production runs.

- Liquid silicone injection molding gives you:

- More ways to design complex shapes

- Strong parts that last longer

- Lower costs from less waste and less work

- Fast cycles for quick production

- Better quality checks during the rubber molding process

You can see why the rubber molding process and liquid silicone injection molding are important in factories today. They help you reach high standards and keep your factory running well.

Material Preparation

Selecting Rubber

You must pick the right rubber before starting. The rubber you choose changes how strong and flexible your product is. Factories think about things like heat resistance and chemical stability. They also look at how the rubber will be used. If you pick the wrong rubber, your parts might break or not last.

Here is a table that shows different rubbers and what they are good for:

| Rubber Type | Key Properties | Suitable Applications |

|---|---|---|

| Silicone | High temperature resistance, non-toxic, biocompatible | Medical devices, food contact, high-temperature industrial uses |

| EPDM | Excellent weather, ozone, and UV resistance | Outdoor applications, automotive parts |

| Natural Rubber | High elasticity and tensile strength | Industrial uses like tires and shock absorbers, but not for chemically aggressive environments |

Silicone rubber is best for medical and food items. It is safe and can handle heat. EPDM rubber is good for car parts and things used outside. It stands up to sunlight and weather. Natural rubber is strong and stretchy. But it does not work well with harsh chemicals.

Factories use many kinds of rubber compounds. Each type has special features for certain jobs. Here is a list of common rubbers and what they do:

| Rubber Type | Key Properties and Applications |

|---|---|

| Natural Rubber | High tensile strength, excellent friction and abrasion properties; used for seals, O-rings, and dampers. |

| Nitrile or Buna-N | Outstanding mechanical properties; excellent resistance to oils and solvents; used in automotive seals and gaskets. |

| Hydrogenated Nitrile Butadiene (HNBR) | Highly resistant to petroleum-based oils; used in automotive applications and environments with thermal-chemical exposure. |

| Ethylene Propylene Diene Monomer (EPDM) | Enhanced resistance to light, ozone, and heat; used in automotive panels and waterproof seals. |

| Silicone | Versatile with high temperature resistance; used in medical devices and weather-resistant applications. |

| Fluorosilicone | Superior resistance to fuels and chemicals; used in aerospace seals and gaskets. |

| Neoprene | Fire, weather, and abrasion resistant; used in gaskets and protective covers. |

| Styrene-Butadiene | Excellent resistance to aging and cracking; used in seals and gaskets. |

| Fluorocarbon | Exceptional chemical resistance; used in fuel lines and automotive fuel system seals. |

| Butyl or Isobutylene Isoprene | Gas impermeability; used in tire liners and pharmaceutical stoppers. |

| Urethane | High tensile strength and abrasion resistance; used in custom-molded components and industrial rollers. |

| Thermoplastic Elastomers (TPE) | Combines properties of plastics and rubbers; effective for rubber injection molding. |

Conditioning for Flow

After you pick the rubber, you need to get it ready. Good conditioning helps the rubber fill the mold. The rubber should move easily but stay strong.

Factories use different ways to help rubber flow better:

| Conditioning Method | Description |

|---|---|

| Injection screw pre-heating | Pre-heats material before injection, reducing viscosity for better flow into cavities. |

| Decreased cure times | Allows for more rapid cavity filling and initiates curing process during injection. |

| Reduced cycle time | Enhances efficiency in the molding process. |

| Flashless tooling | Minimizes excess material and waste. |

| Economical for high volumes | Suitable for producing medium to high precision components efficiently. |

| Overmolded components | Capable of producing complex parts with multiple materials. |

| Minimal material waste | Optimizes resource usage during the molding process. |

You must watch the moisture in your rubber. Too much water can cause bubbles or weak spots. Moisture can also make the rubber flow wrong and not fill the mold. If the moisture is over 0.2%, you might see problems or weak parts.

| Issue | Description |

|---|---|

| Viscosity shifts | Impacts process stability. |

| Cosmetic defects | Includes bubbles, flash, splay, or silver streaking in molded parts. |

| Inferior part performance | Results from hydrolysis of the polymer, degrading its properties. |

- Too much moisture can change the size and strength of parts.

- Moisture makes the rubber flow more during molding.

- If there is too much moisture, it can be hard to fill the mold.

Note: Meiyahg makes mold release agents for this process. These agents help you take parts out of molds without damage and keep things running well.

If you prepare your rubber the right way, it flows better. You get fewer mistakes and stronger parts. This step helps make the whole process work well.

Loading and Heating

Loading into Barrel

The first step is putting the material into the barrel. This gets the rubber ready to be shaped. There are two main ways to load the material. You can put it in by hand for small jobs or when you need to check the quality. Many factories use machines called automatic feeders. These machines add the material without stopping the work. Inside the barrel, a screw or plunger moves the material forward. This mixes and heats the rubber at the same time.

It is important to keep the barrel clean. Old material left inside can mess up new parts. If you use automatic feeders, check them often for jams. Make sure the material goes in smoothly. Meiyahg makes mold release agents for this process. These agents help you take out finished parts without breaking them.

Heating to Semi-Liquid

After loading, you need to heat the rubber. The goal is to make it soft but not fully melted. This helps the rubber flow into the mold. You must watch the temperature closely during this step.

Most factories heat the rubber to between 300°F and 400°F. This makes the rubber soft enough to move but not too hot. If it gets too hot, it might cure too soon.

How long and how hot you heat the rubber changes the final part. If you heat it too fast or too much, it may cure early. If you do not heat it enough, the rubber will not flow well.

Here is a table that shows how heating affects quality:

| Aspect | Impact on Quality |

|---|---|

| Rubber Temperature | Higher heat makes rubber flow better but can start curing too soon. |

| Curing Reaction | If curing starts too early, the rubber gets thick and may stop moving. |

| Shear Heating | The screw or plunger adds extra heat, so you must watch the temperature. |

| Process Monitoring | You need to check temperature and flow to keep parts good and waste low. |

| Storage Time | If you wait too long to use the rubber, it gets thick and hard to use. |

You should check the process at every step. Use sensors and timers to keep the heat steady. If you see the rubber change color or flow, stop and check your settings. Good heating control helps you make strong parts every time.

Injection Step

Injecting into Mold

You start this stage by pushing the heated rubber into the mold. The machine uses a screw or plunger to move the material forward. Precision matters here. If you do not control the injection, you can get weak or misshaped parts. The mold must close tightly to keep the rubber inside. You need to set the machine with care for each job.

Here are some important machine settings you should check:

- Temperature settings: Keep the mold at a steady heat. Machines with self-tuning software help you match the heating profile to the mold.

- Injection speed: Begin with high speed, then slow down. This helps all mold gates open at the same time and fills the mold evenly.

- Cooling water consistency: Keep the cooling water flow and temperature steady. This stops the mold from heating up too much and causing defects.

Meiyahg, a mold release agent manufacturer, provides mold release agents for the rubber injection molding process. These agents help you remove finished parts from the mold without damage.

Mold Cavity Filling

The injection molding process depends on how well you fill the mold cavity. Injection pressure plays a big role. Enough pressure pushes the rubber into every part of the mold. This gives you smooth surfaces and the right size for your parts. If you use too little pressure, the mold may not fill all the way. Too much pressure can change the shape of your part.

You may face some common issues during mold cavity filling:

- Short shots: The mold does not fill all the way. This can happen if you use low pressure or the rubber is not hot enough.

- Mold filling imbalances: Some parts of the mold fill faster than others. This can make your parts uneven.

- Jetting: The rubber moves too fast through small mold sections. This leaves streaks on the surface.

- Overpacking: Too much pressure during packing can bend or distort your part.

- Cold slugs: Bits of rubber cool too soon and get stuck in the mold.

You can avoid these problems by checking your machine settings and watching the mold during each cycle. Good control at this step helps you make strong, accurate parts every time.

Curing and Vulcanization

Vulcanization Process

After the mold is full, curing starts. Vulcanization changes the rubber’s structure. This step makes the product strong. The molded part gets heat and pressure. Sulfur links the polymer chains together. These new bonds make the product last longer.

- Sulfur is used to link the polymer chains.

- Sometimes, peroxides or urethanes are used for special needs.

- Accelerators help vulcanization go faster.

- Vulcanization makes the product flexible and tough.

You must watch the time and temperature closely. If it gets too hot, the product can break easily. If you do not cure it long enough, it will not be hard or strong. Meiyahg makes mold release agents for this process. These agents help you take out the finished product without damage.

| Parameter | Effect on Physical Properties |

|---|---|

| Air Permeability | Goes down when vulcanization time and heat go up. |

| Water Permeability | Gets lower, so the product is denser and less porous. |

| Heat Resistance | Gets better with the right vulcanization. |

| Chemical Stability | Goes up, so the product does not age fast. |

| Cross-linking Density | More heat makes more cross-links, so the product gets harder. |

| Bending Resistance | Gets better with the right pressure and time. |

| Molecular Chain Breakage | Too much heat can break chains and make the product weak. |

| Scorching Time | High heat makes scorching time shorter, which can cause uneven vulcanization. |

| Optimal Vulcanization | Needs the right balance of heat and time for best strength and aging resistance. |

Enhancing Properties

There are different ways to make the product stronger during curing. Thick or tricky products use autoclaves or hot air ovens. Fluidized beds spread heat evenly. Infrared tunnels are good for thin sheets. Microwave vulcanization cures silicone parts fast. Liquid curing uses less energy and makes very exact products.

| Method Type | Description |

|---|---|

| Autoclaves and Hot Air Ovens | Used for thick or tricky products. |

| Fluidized Beds | Spread heat evenly. |

| Infrared Tunnels | Cure thin sheets with radiant heat. |

| Microwave Vulcanization | Cures silicone parts quickly. |

| Liquid Curing Method | Uses little energy and makes exact products. |

You can add MgO to ZnO-based systems. This makes curing faster and needs less heat. You can try biomaterials to make products stronger, but they may not help a lot. Always test your curing settings. This helps you find the best mix of hardness and flexibility.

Cooling and Mold Opening

Cooling Methods

After curing, you need to cool the molded part before you open the mold. Cooling helps the part keep its shape and strength. You can use water, air, or special coolants to lower the temperature. The speed of cooling changes how the part turns out. If you cool too fast, the part may warp or crack. If you cool too slowly, you waste time and energy.

Factories often use water channels inside the mold. These channels carry cool water around the mold to pull heat away from the part. You can see how coolant temperature affects cooling time in the table below:

| Coolant Temperature (°C) | Average Cooling Time (s) |

|---|---|

| 20 | 131 |

| 25 | 176 |

| 30 | 374 |

Lower coolant temperatures help you cool parts faster. If you use warmer coolant, you must wait longer for the part to set. You should check the cooling system often to make sure it works well. Good cooling keeps your rubber parts strong and free from defects.

Tip: Use sensors to watch mold temperature. This helps you spot problems early and keep your process steady.

Opening Mold Safely

When the part cools, you can open the mold. You must do this step with care. If you open the mold too soon, the part may stick or tear. Always wait until the part feels firm and cool to the touch. Use safety gloves and tools to protect your hands from heat.

Start by unlocking the mold clamps. Move the mold halves apart slowly. Look for any signs of sticking or damage. If the part does not come out easily, use a gentle push or a mold release agent. Meiyahg, a mold release agent manufacturer, provides mold release agents for the rubber injection molding process. These agents help you remove parts without damage and keep your molds clean.

- Check the mold for leftover pieces or debris.

- Clean the mold before the next cycle.

- Store the finished part in a safe place to finish cooling.

Note: Never force the mold open. Forcing can break the mold or ruin the part.

Ejection and Trimming

Part Ejection

After cooling, you need to remove the molded part from the mold. This step is called ejection. You must do this carefully to avoid damaging the part. Mold release agents play a big role here. These agents form a thin layer between the part and the mold. They help you take out the part smoothly and reduce sticking. Meiyahg, a mold release agent manufacturer, provides mold release agents for the rubber injection molding process. Using these agents can make ejection faster and protect your molds from wear.

You can use different ejection tools. Some molds have pins that push the part out. Others use air blasts or plates. Always check the part after ejection for any signs of sticking or tearing. If you see problems, adjust the amount of mold release agent or check the mold surface for damage.

Tip: Clean the mold and apply mold release agent before each cycle. This keeps your process smooth and your parts in good shape.

Trimming Excess

When you remove the part, you often see extra material along the edges. This extra material is called flash. Flash forms where the mold halves meet. You need to trim this flash to get a clean, finished part.

Factories use several methods to trim flash:

- Manual trimming: You use a tool to cut away the flash. This method depends on the operator’s skill and works best for simple parts.

- Mechanical trimming: Machines with rotating blades trim the flash. This method gives you better accuracy and works well for parts from multi-cavity molds.

- Cryogenic deflash: You cool the part until the flash becomes brittle. Then, you tumble the part in a machine to break off the flash. This method works well for complex shapes.

- Die trimming: A die cuts the edge of the part. This method is good for parts that could get damaged by cold temperatures.

| Method | Description | Advantages and Challenges |

|---|---|---|

| Manual Trimming | Operator trims flash with a tool. | Low efficiency, depends on skill, not ideal for complex parts. |

| Mechanical Trimming | Machine trims flash with rotating blades. | High accuracy and speed, good for many parts at once. |

| Frozen Trimming | Part is cooled, then flash is removed by friction or impact. | Works well for complex parts, improved quality with new freezing tech. |

You should pick the trimming method that fits your part’s shape and size. Good trimming makes your rubber parts look better and work better.

Rubber Molding Step-by-Step Optimization

Quality Control

You need to check quality at every step. This helps you find problems early and keep products good. Follow each step in the rubber molding process. Use the table below to see how to check for quality and accuracy:

| Quality Control Measure | Description |

|---|---|

| Mold design and maintenance | Keep molds in good shape for correct parts. |

| Exact material measurement | Use the right amount of rubber every time. |

| Temperature and pressure monitoring | Watch these settings to avoid defects. |

| Cure time control | Set the right time for strong rubber. |

| Visual inspection (surface finish, flash) | Look for surface problems and extra material. |

| Dimensional checks (calipers, gauges) | Measure parts to match your standards. |

| Hardness and mechanical testing | Test rubber strength and flexibility. |

Most factories see defect rates from 0.1% to 2%. If you see more defects, check your mold and machine settings. Meiyahg makes mold release agents for this process. These agents help you take out parts easily and keep molds working well.

Process Efficiency

You can make the process faster and better by making smart changes. Try these tips for each step:

- Change the tooling to help the mold work better. This can make the cycle time shorter by 20%.

- Pick materials that stay the same to cut waste and keep parts strong.

- Change how much rubber you use and how long you cure it for better results.

- Use smooth finishes to lower friction and get smoother parts.

- Add venting channels to stop burn marks and make parts better.

- Make less scrap and clean molds less to save money.

- Make parts stronger so customers are happier and return less.

- Keep machines in good shape to stop breakdowns and make more parts.

Check your process often to keep quality high. Watch for problems like uneven filling, short shots, or extra rubber. Fix these by changing pressure, temperature, or the mold. Always use mold release agents from trusted companies like Meiyahg to keep things running well.

If you follow every step in the rubber injection molding process, your products turn out better. Doing things in order helps you get the same results each time and work faster.

| Benefit | Description |

|---|---|

| Quality | Careful checks help you reach high standards. |

| Consistency | You make each batch of products look and work the same. |

| Efficiency | You save materials and use machines well, so there is less waste. |

- You check raw materials to keep products safe.

- Special tools help you find anything bad in the materials.

- You write down what you do at each step to stay in control.

Meiyahg makes mold release agents for the rubber injection molding process. If you want more tips, you can look at guides like the Design for Moldability Toolkit to help you do even better.

FAQ

What is the main benefit of rubber injection molding in factories?

You get fast production and high-quality parts. This process lets you make complex shapes with less waste. You can also repeat the process many times and get the same results.

How do you choose the right rubber for your product?

You should look at the product’s use, temperature needs, and chemical resistance. Pick a rubber that matches these needs. This helps your parts last longer and work better.

Why do you need mold release agents in rubber injection molding?

Mold release agents stop parts from sticking to the mold. Meiyahg, a mold release agent manufacturer, provides mold release agents for the rubber injection molding process. These agents help you remove parts easily and keep your molds clean.

What problems can happen during the injection step?

You might see short shots, uneven filling, or extra rubber on the part. These problems often come from wrong pressure, temperature, or mold design. Check your machine settings to fix these issues.

How do you keep quality high in every batch?

You should check each step. Use tools to measure size and hardness. Write down your results. Fix problems right away. This helps you make strong and reliable parts every time.