Plastic injection molding has been around for over a century and has undergone incredible development. In the early days of injection molding, the process was labor-intensive and expensive, making it impractical for many applications. However, technological advancement has made injection molding much more efficient and cost-effective. Today, it is one of the most widely used manufacturing processes globally.

What is Injection Molding?

In simple terms, injection molding is a process used for manufacturing parts by injecting liquid materials into a mold, then letting them cure to a solid state. It’s often used for making large batches of the same pieces of many different parts that are identical. It starts with raw materials, which are mixed and heated to be in a liquid state. This mixture is then forced into a mold and allowed to cool, harden, and take shape.

What is Plastic Injection Molding?

Plastic injection molding is a process that uses injection molding machines to create plastic products. These machines can produce high-quality plastic parts with little effort and production costs. Injection Molding is one of the most popular ways to make plastic products. This method helps raise production output at an industrial level, making it possible for manufacturers to create large quantities of products at once at a low cost.

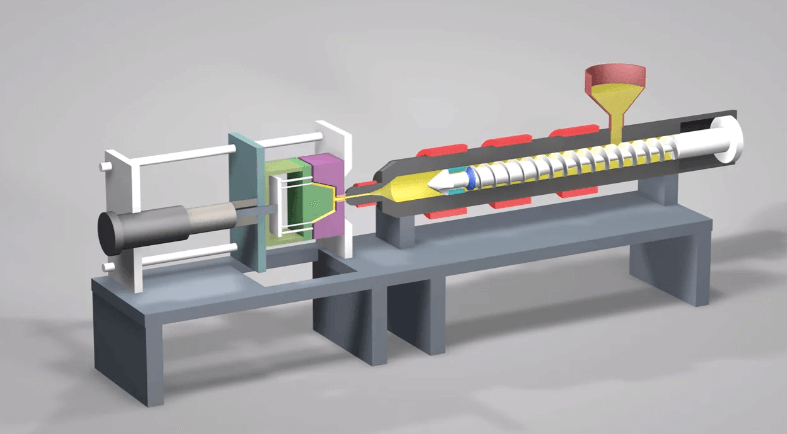

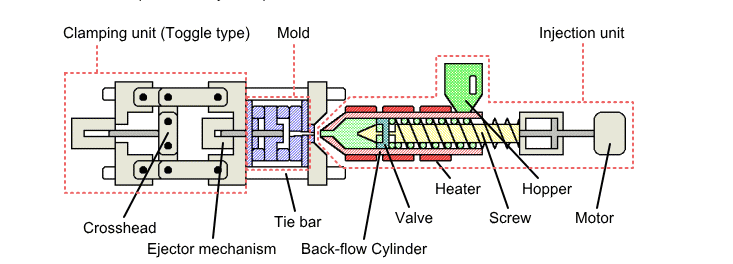

How Plastic Injection Molding Works?

Plastic injection molding works on the same principle as traditional casting. In plastic injection molding, pressure is used to melt and pour liquid plastic into solid plastic. With melting or pressing materials together, plastic injection molding also involves heating a material to place it inside a mold. As the plastic cools and solidifies, it creates the shape of the mold. The finished product is pulled from the mold and ready for use.

What Type of Plastic is Used in Injection Molding?

It’s vital to know about the different varieties of plastics for several reasons, including their cost, ease of use, strength, and more. The type of plastic used in this process can vary based on the type of product you’re looking to produce. There are many types of plastics, each one coming with its own set of advantages and disadvantages. The most common plastics used in plastic injection molding include PC, POM, ABS, Nylon, PMMA, TPU, LDPE, etc. They differ from one another, depending on what use they are put towards. For example, ABS has good impact strength, while PET has a good surface finish. PBT has good chemical resistance, and HDPE has good heat resistance.

What are the Types of Plastic Injection Mold?

There are two main types of plastic injection molds: the cold runner mold, and the hot runner mold.

● The Cold Runner Mold

The more traditional type of mold, a cold runner mold uses cold runner technology. The system consists of a series of channels the melted plastic flows through to reach the mold cavity. The technology uses a cold runner system to inject melted plastic into the mold. This results in a lot of wasted plastic, as the plastic not injected into the cavity is left to harden in the runner system.

Cold runner molds are inexpensive and offer more design flexibility than hot runner molds.

● Hot Runner Mold

A hot runner mold uses a heated runner system to keep the plastic material in a molten form. The molten plastic is then injected into the mold cavity where it cools and hardens to form the desired part. This results in less wasted plastic, as the plastic not injected in can be reused.

Hot runner molds are typically used for high-volume production runs. In addition, hot runner molds can be used to produce parts with complex geometries or multiple cavities.

They offer more precise control over the injection process, which can result in a higher-quality product. However, hot runner molds are more expensive to build and maintain, so they are not always the best option for every application.

What Are The Common Types Of Injection Molding?

There are several different types of injection molding, each with its own advantages and disadvantages.

1. Thermoplastic Injection Molding

Thermoplastic injection molding is a popular manufacturing process for creating plastic parts and components. In this process, molten plastic is injected into a mold and can be cooled and hardened. This process requires special equipment and expertise, but it can be used to create parts with precise dimensions and excellent strength and durability.

It is a versatile process to create various parts and components with different shapes and sizes, which makes it a popular choice for manufacturing plastic parts and components for several reasons. The process is relatively fast and efficient to create products with complex shapes and designs.

2. Thermoset Injection Molding

Thermoset injection molding is a specialized form of injection molding that is used to create parts from thermosetting plastics. Thermosetting plastics are unique that they cannot be melted and reformed like thermoplastic materials, so they must be molded while in a liquid state and then patched afterward. These plastics are known for their high heat resistance and strong, durable properties.

Thermoset injection molding is often used for applications where products can withstand high temperatures or harsh environments. It’s also used in applications that require strength and stability, such as automotive parts and industrial equipment.

3. Polymer Injection Molding

Polymer injection molding is a process in which molten polymer is injected into a mold and allowed to cool and solidify. The mold can be of any shape but is typically in the form of the final product.

Polymer injection molding can be used with various polymers, including thermoplastic and thermosetting polymers. The method is commonly used for the mass production of plastic elements with complex shapes and unique features.

4. Liquid Silicon Injection Molding

Another type of injection molding is liquid silicone rubber injection molding. This process is often used to produce medical-grade silicone parts and products. It is also well-suited for producing parts with complex geometries.

Each type of injection molding has its own advantages and disadvantages. When choosing a manufacturing process, it is important to consider the specific needs of your project.

Why Should You Choose Plastic Injection Molding?

There are countless advantages to using plastic injection molding over the older techniques, but it also has drawbacks over other manufacturing methods.

Advantages of Plastic Injection Molding

1. No Tooling Is Required

This process requires no tooling and reduces the overall costs, making it less expensive for the company and the customer.

2. Easy To Scale

You can make parts in small batches, or you can make them in large quantities. You can also precisely time the production and get consistent quality.

3. Create Large Parts

You can use this process to create large parts, making it perfect if you need to manufacture heavy pieces such as automotive parts and furniture.

4. Flexibility

It’s easy to produce variations of the same part by changing the mold, so you can create different sizes and shapes with different colors and materials, and much more.

Disadvantages Of Plastic Injection Molding

While plastic injection molding has many advantages over other methods, it also has a few drawbacks that must be considered before deciding.

1. Requires Careful Planning

You can’t change the design of a part once you’ve started the process, so you need to ensure everything is planned out beforehand.

2. Can Be Hard To Control The Quality

It’s easy to produce consistent parts when you’re making large batches. However, it can be harder to control the quality of smaller batches.

3. Require High Temperature

High temperatures are required to melt the plastic material and reach the desired temperature for injection.

Applications Of Plastic Injection Molding

Plastic injection molding is one of the most versatile and widely used manufacturing processes to produce parts and products of all shapes, sizes, and complexity.

There are a wide variety of applications for plastic injection molding.

- Automotive parts and components

- Electrical components and connectors

- Medical devices and implants

- Packaging and containers

- Food and Beverage

- Toys and consumer goods

- And much more.

How Much Does Plastic Injection Molding Cost?

If you’ve ever been to a plastics manufacturer, you’ve probably seen the injection molding process. Injection molding is a popular plastic manufacturing method because it’s fast, efficient, and relatively inexpensive.

So, how much does plastic injection molding cost? It depends on several factors, including the size and complexity of the desired product, the type of plastic being used, and the quantity being produced. Generally speaking, the cost of injection molding is determined by the time and labor required to make the desired product. The more complex the product, the more time and labor required, and the higher the cost.

Key Considerations for Achieving The Perfect Plastic Part by Injection Molding

If you’re looking to create a plastic part through injection molding, there are some key things to keep in mind to achieve the perfect result.

- You’ll need to select the appropriate material for your part – different materials have different properties that can affect the final product.

- Then, the design of your part is vital – it should be created with injection molding in mind, as certain features can be difficult or impossible to recreate with this method.

- Also, the injection molding process is crucial to the success of your part – be sure to work with an experienced and reputable company to get the best results.

By keeping these considerations in mind, you can be sure to create a perfect plastic part through injection molding.

What Does The Future Hold For Plastic Injection Molding?

The future of plastic injection molding is bright; it’s expected to grow even further in the coming years. It currently makes up more than one-fourth of the manufacturing industry, which is expected to grow to around one-third in the next decade. Experts say it will take over die casting, machining, and metal stamping as the most common method. There are plenty of reasons why companies across the globe are choosing plastic injection molding over other options, including its versatility, simplicity, and ease of use. It’s expected to become even more popular as new advancements are made, making it more effortless and cost-effective for everyone.

The Final Words

The plastic injection molding industry is growing at a solid rate. In fact, it’s been growing steadily for the last decades. The process is inexpensive and easy to scale up production using injection molding machines. It creates high-quality parts at low costs. In addition, the finished products are reliable and durable.

We hope you find this article insightful and that you’ll continue to check out our blog for information on the metal industry.