Types Of Release Agent

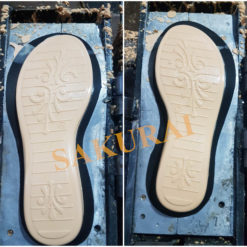

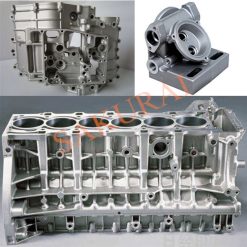

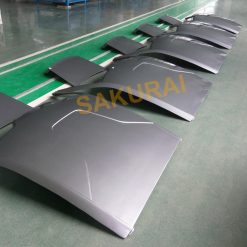

Release agents are widely used in metal die-casting, EVA products, rubber products, plastic products, silicone products, cement products, polyurethane foam and elastomers, glass fiber reinforced plastics, injection thermoplastics, vacuum foam plastic sheets and other material. In our mold release company, we mainly provide the products below:

By Usage: internal release agent, external release agent;

- By Service Life: conventional release agent, semi-permanent release agent;

- By Form: solvent-based release agent, water-based release agent, solvent-free release agent, powder release agent, paste release agent

- By Active Substance:

①Silicon Release Agent-mainly silicone compound, silicone oil, silicone resin methyl branched silicone oil, methyl silicone oil, emulsified methyl silicone oil, hydrogen-containing methyl silicone oil, silicone grease, silicone resin, silicone rubber, silicone rubber toluene solution

②Wax Series-plant, animal, synthetic paraffin; microcrystalline paraffin; polyethylene wax, etc.

③Fluorine Series-the best isolation performance, low mold pollution, but high cost Polytetrafluoroethylene; fluorine resin powder; fluorine resin coating, etc.

④Surfactant Series-metal soap (anionic), EO, PO derivatives (non-ionic)

⑤Inorganic Powder Series-talc, mica, clay, white clay, etc.

⑥Polyether series-a mixture of polyether and fat oil, which has good heat resistance and chemical resistance, and is mostly used in certain rubber industries that have restrictions on silicone oil. The cost is higher than that of silicone oil series.